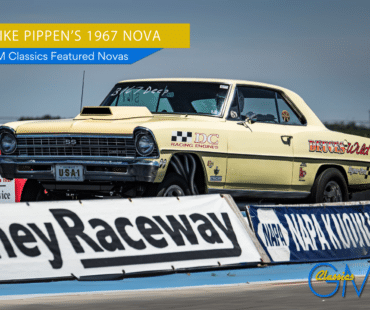

Owner’s Name: Steve Dembinski

Occupation: Builder / Fabricator / Owner – Hot Rods by Steve LLC (732-766-6001)

How long did it take to build the car? 14 months (on & off, working between customer builds)

Please tell us what you believe to be the most unique feature about your car?

The Engine Compartment. A lot of time, thought, engineering and planning went into executing such a sinister look. No visible wires or lines, no unnecessary clutter. Subtle and simple was the design. A lot of thought and engineering went into getting the Big Block Engine to fit beneath the stock “flat” hood. A cowl (even a 2”) was not an option. The motor mounts were machined down as well as the intake plenum on the manifold. A CNC’d air cleaner was made so that it tapered and provided enough clearance for a small piece of trim and to fit under the factory ‘x’ on the underside of the hood.

Names of people who helped build the car, and what they did __

- Built in House by (Hot Rods by Steve LLC – Howell, NJ 732-766-6001): Steve Dembinski, Ken Dembinski, Pat Tyra

- Terry Smith of “Smith Machine”: One off CNC’d Billet Air Cleaner, Billet Washers & Billet Trim

- Mike Lippincott of “Lippincott Custom Auto Upholstery” – Interior Build and Design (256-595-3211)

The Story:

One Sunday afternoon I decided to surf the online classifieds to kill some time. I was NOT in the market to purchase any vehicle. I was “just looking” to see what was out there. There was a “new post” made moments before I logged on and it caught my eye. It read “1967 Nova – All Original”. Having built a few of these before, I knew the body style and was inclined to take a look at the ad. The pictures looked good so I decided to email the seller. I asked the condition of the floor and trunk and if all the parts were still with the car. He replied fairly quickly saying the car was “pretty solid”, had a clean title and was complete but disassembled. The words “pretty solid” and the super low asking price of $5,500 scared me. After a few pictures were emailed back and forth I offered $3,800 without the engine and trans that had been already removed from the vehicle. He accepted and I scheduled a transporter to pick it up (he was in Indiana and I am in NJ). A day later I had buyer’s remorse. I kept thinking of the simple “pretty solid” answer regarding the condition and the quick acceptance of my offer. The day it arrived, I was offered $5,000 on the spot before it even came off the trailer by a passer-by but I quickly refused. I was immediately taken back by the fresh coat of primer and obvious overspray. Then I took a magnet to the car and was amazed that it was all steel! I realized the car had been stripped to bare metal by the previous owner in order to begin restoration and that he must have done a quick primer job so it wouldn’t rust during transit. Inside the car I found boxes full of zip lock bags that were all meticulously labeled. The previous owner took a lot of time disassembling this car. EVERY original part to this car was eventually found in those boxes. The car was 100% complete.

I was still reluctant about the bodys condition and had to see it in bare metal myself. I had the car media blasted and was amazed at the condition that lay underneath. As if it emerged from a time capsule, this car was as solid as it was when it left the assembly line back in 1967. Knowing how solid it was I decided that such a car should be saved and not cut up. (original plans were to build a back-halfed modern day pro-street). So not knowing what to do with the car, I shelved it until I came up with a design concept. It took 3 years for me to realize that I should build a car that most relates to the majority of potential clients inquiring. The purpose of most car enthusiasts that request our service is to have a practical performance, street driven car that sees more road and show time than track time. I love as much as the next guy loves a great piece of eye candy that can out perform the new super cars of today. But, the bottom line is that most people can’t afford such a build and/or it is overkill for their particular situation. It would be like Grandma buying a Ferrari to go grocery shopping.

After a long design and thought process, it was apparent that I should try to meet the majority demand of those who inquire. Car builds can get expensive and carried away so I set out to minimize build cost by lessening the amount of hardcore fabrication (which simply is time multiplied by hourly rate) and focused on attention to detail while using aftermarket bolt-on parts in lieu of over the top fabricated ones. The Nova’s purpose is to show the consumer all the aftermarket products available that are truly bolt-on parts while still maintaining a budget on the overall project . Our personal goal was to have one of the countries nicest bolt-together cars and show the potential of what such a car could look like.

After contacting a few companies about the idea / theme of the build, many jumped on board. The following companies contributed to the “bolt on” theme of the build by providing the following parts:

- Chris Alston Chassisworks: CA Chassisworks is proud of their “No Fab” slogan. Their “BOLT-IN” front kit proved to be one easy install. The kit is complete with frame, inner fenders, Upper and Lower Control arms, Rack & Pinion and Misc. Mounts / Hardware necessary for install. Everything was pre-engineered for a direct Bolt-In and was installed within a few hours. It’s one of the most complete systems on the market and offers several different options in regards to control arms, steering, brakes etc. Using a company that offers more options opens the door for future upgrades.

- Marquez Design: This Nova has the VERY FIRST PROTO-TYPE tail lights in the US. CNC’d Billet Tail Lights. Pasqual and Judas were gracious enough to work with me to proto-type the fitment and installation process as well as wiring on their NOW available billet tail lights!

- Shannon Odom: MODO Innovations: Shannon and I worked very closely to proto-type an electric trunk release kit (for 66/67 Novas) to expand his line of product. This car has the very first kit (still the proto-type in the car). This is a super easy to install kit that requires very little modification to the existing trunk latch.

- Clay Johnson: Clayton Machine Works: Clay is an old friend of my long time upholster. He and I worked close to come up with the first set of Black Pro-Touring Style Door Handles and Window Cranks. This was the proto-type set for marketing reviews. Clay also provided ALL the billet trim spears for the project.

- PRC (Performance Rod & Custom): Provided a truly “made to order” & “bolt-in” radiator kit.. Its a Double Pass design w/ dual Spal 12″ fans and came complete with a relay hook up kit, temp sender control for fan on / off, and billet radiator cap.

- Ring Brothers: Mike Ring sent us a set of Black Anodized Hood Hinges & Black Anodized Door Handles that are a direct bolt on for 67 Novas.

- Total Cost Involved: a TCI 4 Link kit and a complete TCI / Currie 9” Rear Housing proved to be a direct bolt in Performance Kit.

- GM Classics & Chevy 2 Only: LOTS of hard to find restoration pieces. Restoration Products from trim to rubber and everything in between.

Nova Info

Engine & Transmission

- Make: GM Performance Parts

- Type: Iron Block

- Current Displacement: 454 (7.4L)

- Engine Builder: Hot Rods by Steve LLC

- Engine Assembly by: Ken Dembinski & Steve Dembinski

- Machine Work by: Terry Smith of Smith Machine from Howell, NJ

- Bored: 4.25

- Stroked: 4.00

- Balanced: Yes

- Blueprinted: Yes.

- Cylinder heads manufacturer: GM Performance Parts

- Model: Aluminum oval port; 110cc chambers w/ 2.25″ intake and 1.88″ exhaust valves

- Stud kit manufacturer: ARP

- Piston: Forged Aluminum, compression ratio: 9.6:1

- Crankshaft manufacturer: GM Performance; Forged Steel

- Camshaft Manufacturer: Custom Ground; Hydraulic roller

- Intake: Lift: 510, Duration: 211

- Exhaust: Lift: 540, Duration: 230

- Intake manifold manufacturer: Edelbrock

- Model: Torker 2.0 (w/ Machined Intake Plenum for added hood clearance)

- Carburetor manufacturer: Holley, Model: 4150, cfm: 750

- Fuel pump: type: Electric, manufacturer: Holley

- Oil Pan: Mfg: GM Performance Parts, capacity: 4qt

- Water pump Mfg: Edelbrock

- Radiator: Material: Aluminum, rows: Down-Flow, Mfg: PRC (Performance Rod & Custom) Custom Built to Spec w/ Dual 2800cfm Spal Fans)

- Alternator: output: 100amp, Mfg: Tuff Stuff (Powder Coated Case)

- Valve covers: Mfg: Ansen (Heavily Modified and Machined to eliminate Logo etc)_ Material: Aluminum

- Air cleaner housing manufacturer: Hot Rods by Steve Designed and CNC’d by Terry Smith (Smith Machine, Howell NJ)

- Ignition manufacturer :MSD, Model:6AL

- Headers: Mfg: Chris Alston, Chassisworks, size:2-1/8”

- Coating Material: Black Ceramic

- Exhaust system manufacturer: 2-1/2” Borla XR1 Mufflers, Material: S/S

- Engine accessory and dress-up Smooth block & heads, Custom Billet Trim, March Performance Pulleys Powder Coated Black, Hidden Wiring and Fuel Lines

- Estimated horsepower: 440 at 5250 rpm

- Estimated torque: 500 at 3450 rpm

Suspension

- FRONT: Complete Chris Alston Chassisworks Clip

- Spindle manufacturer: Chassisworks, drop: 2”

- A-arms manufacturer: Chassisworks, tubular: yes

- Coil Over manufacturer: QA1, adjustable: Single

- Swaybar: 1” dia, manufacturer: Chassisworks

- Brakes manufacturer: Wilwood, rotor size: 13”, caliper type: DynaPro

- REAR:

- Coil Over manufacturer: QA1, adjustable: Single

- Brakes manufacturer: Wilwood, rotor size: 12.19, caliper type:Dynalite

- OTHER MODIFICATIONS:

- Front: Chassisworks Frame and Components were all smoothed of all exposed Welds. They were all then hand sanded for a flush seamless look.

- Rear: TCI (Total Cost Involved) 4 Link Assembly w/ Center Diagonal Link. Chassis Components were all sanded smooth and powdercoated Matte Black for an OEM look. 4 Link Bars were also sanded smooth and powdercoated a Matte Graphite for contrast.

- Other: Rear Wheel Wells were sliced and widened to be flush with the stock frame rail. A total gain of 2.5” was obtained. The wells were then welded and sanded / ground down smooth and made to look factory and untouched. All was performed by myself (Steve Dembinski) and Hot Rods by Steve Staff.

Wheels & Tires:

- Front-brand: Intro Wheels, Model: ID321, size: 18×8, backspace: 4.5

- Rear-brand: Intro Wheels, Model: ID321, size:19×11, backspace: 4.5

- Front-brand: Hankook, Model: V12 Evo, size: 215/40/18

- Rear-brand: Hankook, Model: V12 Evo, size: 285/35/19

Interior

- Seats: Front: Seat Bottom Mechanics are 1993 Toyota Celica.

- Front Seat Bottom Cushions are Heavily Modified.

- Front Seat Tops 100% Hand Built

- Rear Seat: Top & Bottom are 100% hand built from scratch

- Designed and Built by Mike Lippincott – Lippincott Custom Auto Upholstery

- Covering Material: Ultra-Leatherette – Oxford White & Ebony

- Door and side panels: 100% Hand Built from Scratch using Proto-Type Clayton Machine Door Handles and Window Cranks and Billet Trim Spears. Designed and Built by Mike Lippincott – Lippincott Custom Auto Upholstery

- Dash: Designed by Steve Dembinski (Hot Rods by Steve) and 100% Hand Built by Mike Lippincott – Lippincott Custom Auto Upholstery

- Carpets: Mercedes Benz, color: Jet Black

- Console: manufacturer or custom builder: 100% Hand Built from Scratch. Designed and Built by Mike Lippincott – Lippincott Custom Auto Upholstery

- Upholstery installer: Mike Lippincott – Lippincott Custom Auto Upholstery (256-595-3211)

- Glass: manufacturer or source: Auto City Classic Glass – Custom Made NON TINT glass. There is zero tint in ANY of the glass pieces!

- Instrumentation/gauges manufacturer: Classic Instruments

- Model of gauges: All American Tradition

- Interior Wiring: Hot Rods by Steve Custom Harness, Painless Wiring Fuse Block, Auto Rod Controls Switch Panel

- Wiring Installed by: Ken Dembinski (Hot Rods by Steve)

- Steering wheel manufacturer: Billet Specialties

- Shifter manufacturer: B&M, Model: Street Bandit

- Other custom interior features: Trunk designed to resemble a modern day luxury car. OEM Grey/Black material w/ Subtle ‘x’ pattern in trunk lid. Remote Battery terminals for charging and HALON Fire Extinguisher for safety. Electric trunk release kit by MODO Innovations

Exterior

- Color: Steel Blue (2008 Chrysler), paint brand and type: Sherwin Williams (2 Stage)

- Grille manufacturer: OEM (Restored by G&L Metal Polishing – Jackson NJ)

- Front bumper/roll pan manufacturer: OEM

- Rear bumper/roll pan manufacturer: OEM

- Stainless Restoration by George Lucas – G&L Metal Polishing – Jackson NJ

- Describe other custom bodywork: Custom altered and Smoothed Firewall. Filled and Smoothed radiator support. Custom Front Radiator Filler (Valance), Filled and Smoothed Cowl Panel and eliminated Wipers. Shaved Door Locks. Shaved and Smoothed Door Jambs. Shaved and Smoothed Rocker Pinch Welds. Filled and Smoothed body seams. Reshaped trunk line. Smoothed Inner Fender Panels, Wheel Wells and Lower Valance. Shaved Exterior Mirrors. Eliminated Unnecessary Body Clutter from Engine Compartment. ALL Exterior Trim was Powdercoated Matte Black to resemble “newer” vehicles. Underside of Body was Stripped, Smoothed and Sprayed in “Raptor” bedliner material

Leave a Reply